Famous American factories that turned to rust

From boom to rust

In the early 20th century, Midwestern cities were booming. There were plenty of jobs in the burgeoning manufacturing industry, where everything from meat to motorcars was being produced at speeds never seen before. But in the century since, new technology and cheap labor have changed the face of manufacturing, luring factories to foreign shores.

Although some of these plants have been preserved, others, once the jewels in the Midwestern crown, lie abandoned. Read on to see the haunting photos of America's famous Midwest factories that are no more.

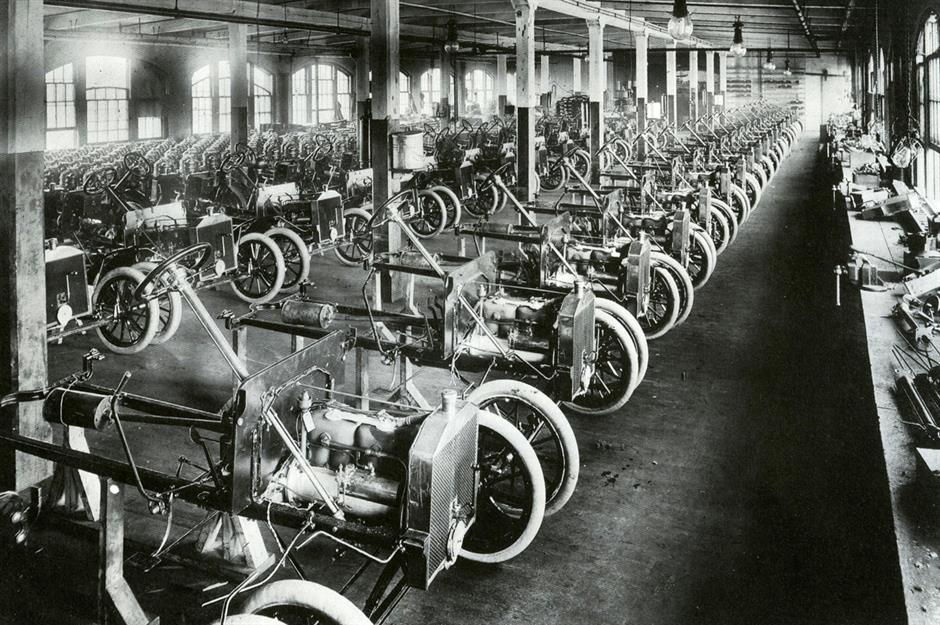

Ford Piquette Plant, Detroit, Michigan

Detroit, aka Motor City, was once the epicenter of the American automotive industry. This was thanks in part to Henry Ford, who established his factories around Piquette Avenue. Built in 1904, the Ford Piquette Plant is the birthplace of the Model T, the world's first mass-produced car. It was also the first automotive factory to operate an assembly line, an innovation that changed manufacturing forever.

Standing on three acres of land, the huge building used 355 double-hung windows to admit natural light and ventilation to make life more comfortable for the thousands of people who worked there. The facility was also one of the first to feature a sprinkler system, something Ford himself insisted on after a fire destroyed one of his other factories in 1901.

Ford Piquette Plant, Detroit, Michigan

At its peak, the Piquette Plant was churning out over 100 cars a day. By 1910, this success meant that Ford had to move to a bigger plant, so he sold the site to Studebaker. Although Studebaker closed its doors in 1967, the plant remained a car manufacturer for most of the 20th century, even as it was shunted from owner to owner. It finally fell into disrepair in the 1980s, as car companies left Detroit in droves.

Ford Piquette Plant, Detroit, Michigan

Arguably, this building is one of the most important sites in the history of cars, American industry, and global manufacturing. But in 1998, it was at risk of demolition. The Henry Ford Heritage Association spent 10 years fighting to save the building from ruin, eventually managing to stabilize the foundations and preserve the site for the future. The former factory is now home to the Ford Piquette Avenue Plant Museum.

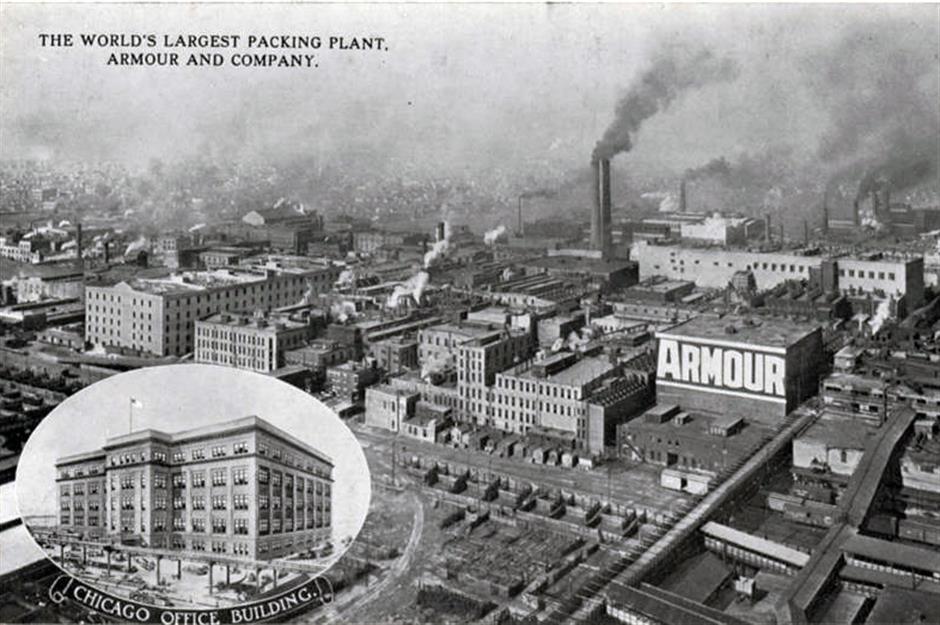

Armour Meat Packing Plant, East St. Louis, Illinois

Illinois, particularly the region around Chicago, has a strong industrial heritage, especially in meat processing and packaging. By the start of the 20th century, the Chicago Union Stockyards employed 25,000 people and produced 82% of the domestic meat consumed nationally. Brothers Philip and Joseph Armour had their first meatpacking plant in the stockyard, before moving to set up a bigger operation in East St. Louis. There, they built the Armour Meat Packing Plant in 1900.

Armour Meat Packing Plant, East St. Louis, Illinois

Henry Ford is often credited with developing the assembly line, but Philip Armour was actually one of its earliest implementers. He designed assembly lines for slaughtering animals and built a 12,000-strong fleet of refrigerated rail cars. This enabled him to transport meat without it spoiling on the journey. He also tried to use every part of the animals he killed, selling by-products for glue, cosmetics, and fertilizer. In its heyday, the factory employed 4,500 people.

Armour Meat Packing Plant, East St. Louis, Illinois

Although Armour died in 1901, the plant continued to thrive. Before World War II, it was one of the largest in America. People even came to visit the plant as a tourist attraction, drawn by its macabre production line and 210-foot smokestacks. But as refrigeration changed the meatpacking industry in the 1950s, the Armour plant was eventually forced out of business. It shut its doors in 1959 and, after lying abandoned for around fifty years, was eventually demolished in 2016.

Fisher Body Plant 21, Detroit, Michigan

The Fishers were one of the founding families of the American car industry. They built horse-drawn carriages from the mid-1800s and invested heavily in auto manufacturing as early as 1900. In 1908, they moved from Norwalk, Ohio to Detroit to launch the Fisher Body Company, a firm that quickly became the world's largest manufacturer of auto bodies.

The company had eight sites around Piquette Avenue in downtown Detroit, the biggest of which was Fisher Body Plant 21 (pictured). In 1919, the company was sold to General Motors but retained its name and sites. At one point, the business employed over 100,000 people worldwide.

Fisher Body Plant 21, Detroit, Michigan

By 1916, the Fisher Body Corporation had a capacity of 370,000 car bodies per year. Its customers included Abbot, Buick, Cadillac, Chalmers, Chandler, Chevrolet, Ford, Herreshoff, Hudson, Oldsmobile, Packard, and Studebaker. But when fully integrated chassis were invented, many car companies began to produce the parts they needed in-house, eliminating the need for third-party companies such as Fisher Body.

In the 1950s, the plant was repurposed by Cadillac and changed hands several times over the next 30 years. It's been out of use since 1993 and the city of Detroit officially took ownership of the building in 2000. It quickly became a popular spot with urban photographers who have documented the plant's decline.

Fisher Body Plant 21, Detroit, Michigan

After Detroit declared bankruptcy in 2013, it started working on plans to regenerate its downtown area and bring much-needed growth to the city. The authorities spent years looking for developers to renovate Fisher Body Plant 21, after launching a $1 million project to start ridding the building of asbestos and other dangerous materials. Proposals have ranged from nightclubs and condos to museums and 'modular facilities.'

Work is now underway to turn the building into Fisher Lofts, a mixed residential and commercial space that's expected to open in 2027.

Swift and Co. Meatpacking Plant, Sioux City, Iowa

Built as the Midland meatpacking plant in Sioux City, Iowa in 1919, this vast plant was originally meant to rival the prominence of the Chicago stockyards. It never took off and was closed just one year later, sitting unused until 1924. It was eventually bought by Swift and Co., the biggest meatpacker in the world, but after a series of workers' strikes and floods, the beleaguered plant closed its doors in 1974.

Swift and Co. Meatpacking Plant, Sioux City, Iowa

It reopened as the KD Station, a shopping mall and entertainment venue. The building was considered of such importance that it was listed on the National Register of Historic Places. However, in 2004, it caught fire and was irreparably damaged.

Swift and Co. Meatpacking Plant, Sioux City, Iowa

The owners declared they could no longer maintain the building, and the city declared it unsafe, forcing the remaining businesses to relocate. In 2006, arsonists set fire to the empty building, causing further damage. In 2010, more than 90 years after it was built, the factory was finally torn down.

Hudson Plant, Detroit, Michigan

The Hudson Car Company was founded in 1908 and quickly became one of Detroit's big players. The company's aim was to produce affordable vehicles, and it sold over 4,000 units of its Model 20 in the first year of manufacturing. By 1925, Hudson was the third-largest carmaker in America behind Ford and Chevrolet.

Hudson Plant, Detroit, Michigan

Before World War II, Hudson employed over 17,000 people across its plants. When war broke out, the company pivoted to war effort production, including the construction of parts for army bombers (pictured here).

Hudson Plant, Detroit, Michigan

By the mid-1950s, its once cutting-edge manufacturing was becoming outdated. Demand grew for sleeker cars that were much easier to assemble. Automobile company Chrysler took over some of the Hudson plants, while others were destroyed.

Chevrolet Plant, Muncie, Indiana

Detroit might be described as Motor City, but Muncie, Indiana once boasted almost as many car plants. A thriving industrial destination in the early 20th century, Muncie was home to iron and steel mills and was also the capital of the Ball Brothers' glass empire. Many companies invested in the town, but one of the most prominent was Chevrolet.

Chevrolet Plant, Muncie, Indiana

The Chevrolet-Muncie plant was among the largest manufacturing sites in the area, employing thousands of people at its peak. In 1935, the plant began manufacturing transmissions for cars and trucks. It built a number of new facilities throughout the 1950s and 1960s to accommodate its growing product line, but this winning streak wasn't to last.

Chevrolet Plant, Muncie, Indiana

The company later faced a series of recessions and workers' strikes, forcing it to close facilities across the country. The Chevrolet-Muncie plant was among them. The factory closed in 2006 after a number of unsuccessful partnerships. Later plans to build a solar field on the site were abandoned. According to the Indiana Business Journal, Indiana has lost more than 20,000 car manufacturing jobs since 1999.

Packard Plant, Detroit, Michigan

The Packard Automotive Plant was one of the largest plants in Detroit, making luxury cars for the Packard Motor Car Company and later the Studebaker-Packard Corporation. The four-million-square-foot plant was located on 40 acres of land, once a cow pasture, on the city's east side. A major development when it was built, the Packard Plant included the first use of reinforced concrete in America and employed skilled workers in more than 80 trades.

Packard Plant, Detroit, Michigan

But as the automobile bubble burst in the late 1950s, Packard's business model couldn't keep up and the company went bust in 1956. Two years later, the last plant caretaker left the building.

Over the next 40 years, the plant changed hands several times. By 1998, the city of Detroit had taken ownership of the building and initially planned to demolish it. This didn't happen for a while as the last tenant didn't leave the building until 2010, and the factory stood derelict.

Packard Plant, Detroit, Michigan

It was the largest abandoned factory in the world, visited only by graffiti artists and scrappers on the hunt for metal. The site went through several owners, but various plans for redevelopment were abandoned. Though the city reportedly planned to save some parts of the building to preserve its legacy, all structural components of the plant were demolished by December 2024.

Auto Armageddon? Why the EV revolution has sparked a car industry crisis

Comments

Do you want to comment on this article? You need to be signed in for this feature